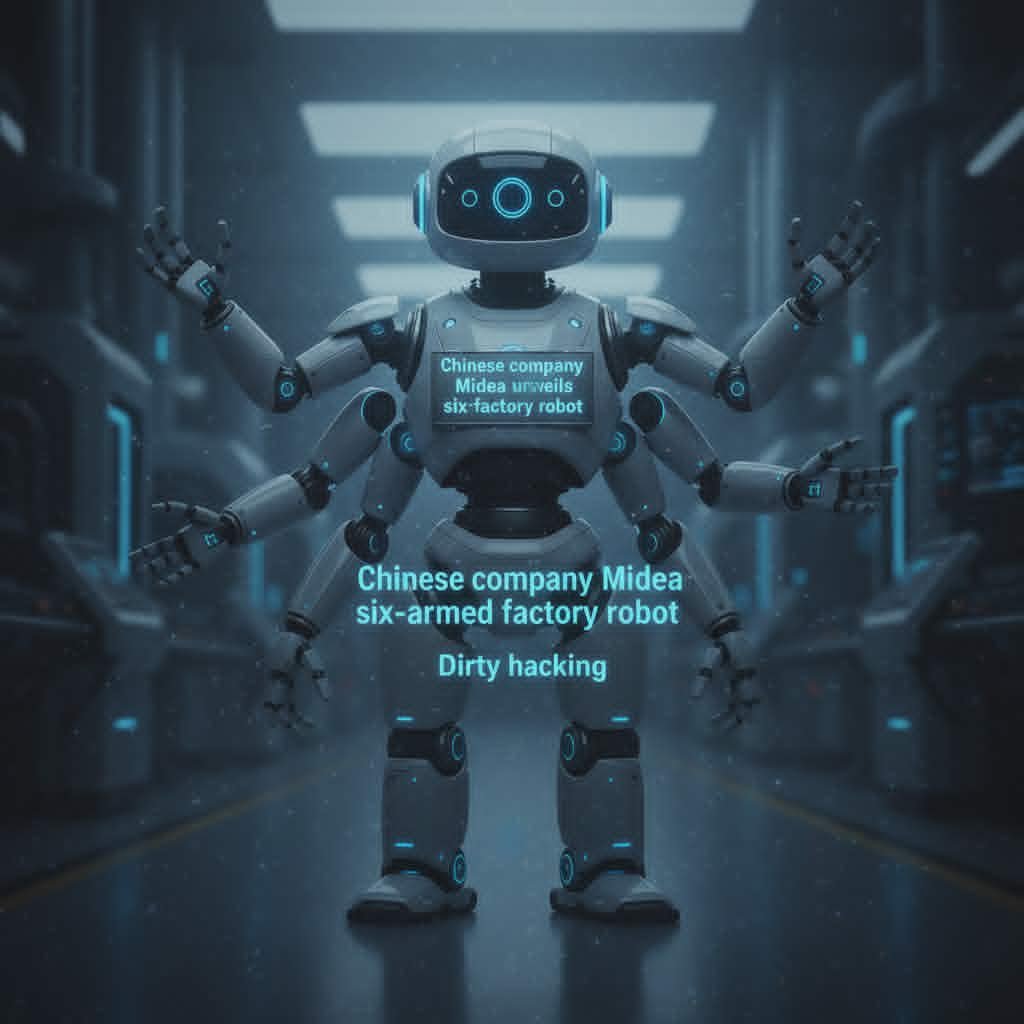

Chinese technology and home-appliance giant Midea has revealed a new human-like robot designed to change how factories operate. The robot is part of the company’s push to increase automation and improve efficiency in manufacturing.

Named MIRO U, the robot is equipped with six robotic arms that can work together in perfect coordination. Unlike traditional factory robots, which are usually fixed in one place, MIRO U is mounted on a mobile wheeled base, allowing it to move freely around the factory floor. This makes it more flexible and useful in modern production environments.

Each of the robot’s arms can carry out different tasks at the same time. These include assembling small parts, lifting heavy components, switching tools, and handling multiple production steps in parallel. This ability to perform several jobs at once helps speed up manufacturing processes and reduces downtime when production lines need to be changed.

Midea says the robot can increase efficiency by up to 30%, particularly during machine operation and when factories reconfigure their production lines. This could help manufacturers save money, improve output, and respond more quickly to changes in demand.

The robot is designed to work alongside human employees rather than fully replace them. By taking over repetitive, dangerous, or physically demanding tasks, MIRO U allows workers to focus on quality control, supervision, and more skilled work.

Experts say developments like MIRO U reflect a wider trend in global manufacturing, where companies are investing heavily in robotics to deal with labour shortages, rising costs, and the need for faster production. As automation continues to advance, robots like MIRO U may soon become a common sight in factories around the world.

Leave a Reply